When it comes to the foundry industry, various machines play crucial roles in streamlining the casting process. Among them, decoring machines and shakeout machines are commonly used. While both machines serve distinct purposes, understanding their differences and benefits is essential for efficient foundry operations. In this article, we will explore the features, functionalities, and advantages of decoring machines and shakeout machines, providing a comprehensive comparison between the two.

Decoring Machines

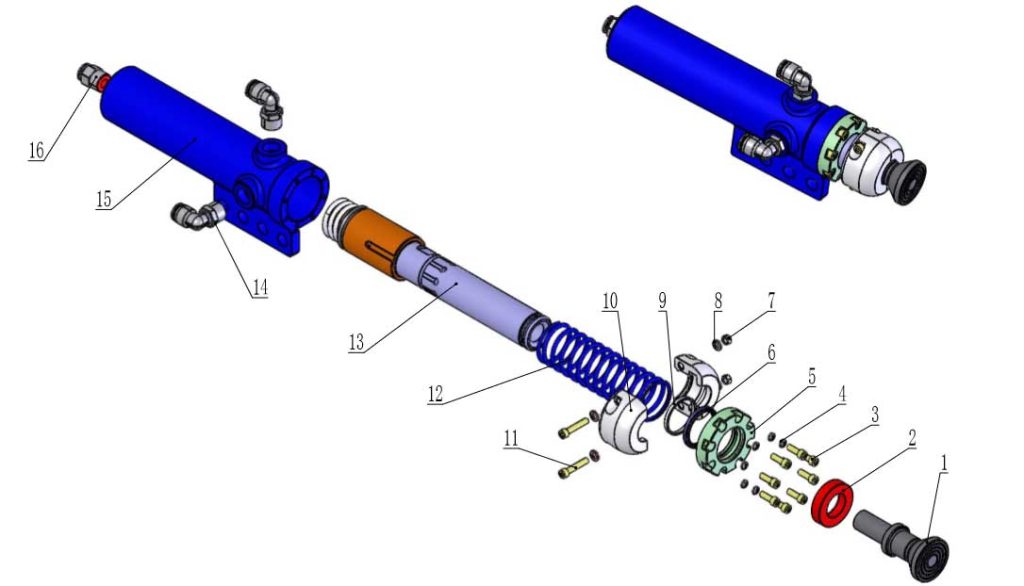

Decoring machines are designed specifically to remove cores from castings. They automate the decoring process, enhancing productivity and precision. Here are the key aspects to consider when evaluating decoring machines:

Working Principle

Decoring machines employ various techniques such as mechanical impact, thermal methods, or a combination of both to break down and remove cores from castings. The specific method depends on the type of casting and the core material used.

Application Range

Decoring machines are versatile and can handle a wide range of castings, including those made from aluminum, iron, steel, and other alloys. They are commonly used in industries such as automotive, aerospace, and manufacturing.

Efficiency and Precision

Decoring machines offer high efficiency and accuracy in core removal. They can handle complex castings with intricate core designs, ensuring minimal damage to the casting itself. The automation provided by decoring machines reduces labor-intensive manual work and increases overall productivity.

Customizability

Decoring machines can be customized to meet specific requirements. This includes adjustable parameters such as impact force, temperature, and core removal speed. Such flexibility allows foundries to optimize the decoring process for different casting types and core materials.

Shakeout Machines

Shakeout machines, on the other hand, are primarily used for the removal of sand and other debris from castings. They employ vibration or oscillation to dislodge the sand from the casting surface. Let’s explore the characteristics of shakeout machines:

Vibration Mechanism

Shakeout machines utilize a vibrating mechanism to shake the castings, causing the sand to separate from the surface. This action helps in efficient sand removal without damaging the casting.

Sand Reclamation

Shakeout machines not only remove sand but also aid in the reclamation process. They separate the sand from the castings, making it easier to recycle and reuse the sand in subsequent casting processes. This contributes to cost savings and environmental sustainability.

Cleaning Efficiency

Shakeout machines ensure thorough cleaning of the castings by effectively dislodging sand, core fragments, and other debris. This leads to improved casting quality and reduces the need for manual cleaning or secondary operations.

Compatibility

Shakeout machines are suitable for various casting materials, including iron, steel, and non-ferrous alloys. They find applications in foundries of all sizes, ranging from small-scale operations to large-scale industrial facilities.

Decoring Machine vs. Shakeout Machine

A Comparison To better understand the differences between decoring machines and shakeout machines, let’s compare them across several key aspects:

| Aspect | Decoring Machine | Shakeout Machine |

|---|---|---|

| Core Removal | Specifically designed for core removal | Primarily focuses on sand removal |

| Foundry Application | Suitable for various casting materials and industries | Widely used in foundries of all sizes |

| Automation | Highly automated, reducing manual labor | Offers automation in the sand removal process |

| Cleaning Efficiency | Ensures minimal core residue | Efficiently removes sand and debris |

| Precision | Minimizes casting damage during core removal | Preserves casting integrity while removing sand |

| Sand Reclamation | Not applicable | Facilitates sand reclamation and recycling |

| Customization | Adjustable parameters for different casting and core types | Limited customization options |

| Cost Considerations | Initial investment and operational costs | Initial investment and operational costs |

Final Words

Decoring machines and shakeout machines each serve specific purposes in the foundry industry. Decoring machines excel in precise core removal, customization options, and versatility, while shakeout machines are highly efficient in removing sand, aiding in reclamation, and preserving casting integrity. Choosing the right machine depends on the specific needs of a foundry, considering factors such as casting types, production volume, and cost considerations. By understanding their unique features and benefits, foundries can make informed decisions to optimize their casting processes.

In conclusion, both decoring machines and shakeout machines play crucial roles in enhancing efficiency and productivity in foundry operations. By investing in the right machine for the intended purpose, foundries can achieve improved casting quality, reduced manual labor, and overall cost savings, contributing to their long-term success.