The best solution for aluminum casting decoring

De-coring Station,

Decoring Machine

BIT Decoring Machine offer high efficiency and accuracy in core removal, and can handle complex castings with intricate core designs, ensuring minimal damage to the casting itself. The automation provided by BIT decoring machines reduces labor-intensive manual work and increases overall productivity.

About BIT Decoring Machine

BIT’s decoring machine and decoring station offer high efficiency and accuracy in core removal, they can handle complex castings with intricate core designs, ensuring minimal damage to the casting itself. The automation provided by BIT decoring machines reduces labor-intensive manual work and increases overall productivity.

In BIT, decoring machine can be customized to meet specific requirements. This includes adjustable parameters such as impact force, temperature, and core removal speed. Such flexibility allows foundries to optimize the decoring process for different casting types and core materials.

Features of BIT Decoring Machine

- Fast & Reliable Decoring: High Productivity Combined With Simplicity

- Safe & Environmentally Friendly: Minimal Moving and Wearing Components

- Short Cycle Times: High Efficiency and Low Energy Consumption

- Customizable design to be suitable for virtually any casting and batch production of various scale production lines

- Fully Programmable Cycle Enabling: Easy to Integrate Into the Assembly Line and Allows the End User to Match the Decoring Machine’s Operation to the Core Extraction Requirements

DC Series De-coring Machine Types and Parameters

The following list shows DC Series’ best-selling models. Of course, we also provide other functional combination models, and specially customized non-standard series are not included here.

| Model | DC-70 | DC-70R | DC-70V | DC-70RV |

|---|---|---|---|---|

| Shakeout | Manual | Rotary | Vibration | Rotary & Vibration |

| Max. Workstations | 4 | 4 | 4 | 2 |

| Max. De-coring Hammes | 8 | 8 | 8 | 4 |

| Recommended Applications | Housings, Air Manifolds | Housings, Air Manifolds | Housings, Air Manifolds, Cylinder Heads, Control Arms, and Subframes. | Housings, Air Manifolds, Cylinder Heads, Control Arms, and Subframes. |

Other Parameters

Hammering Frequency: The hammering frequency varies under different air pressures:

• 0.4 MPa: 19, 19.5, 21.1 Hz

• 0.5 MPa: 19.5, 21.1, 23.6 Hz

• 0.6 MPa: 21.1, 25.7 Hz.

Sand Removal and Conveying Method: The standard configuration includes a waste sand collection cart; a waste sand belt conveyor is available as an optional upgrade.

DECORING UNIT/ DECORING STATION

DC-70 De-coring Machine

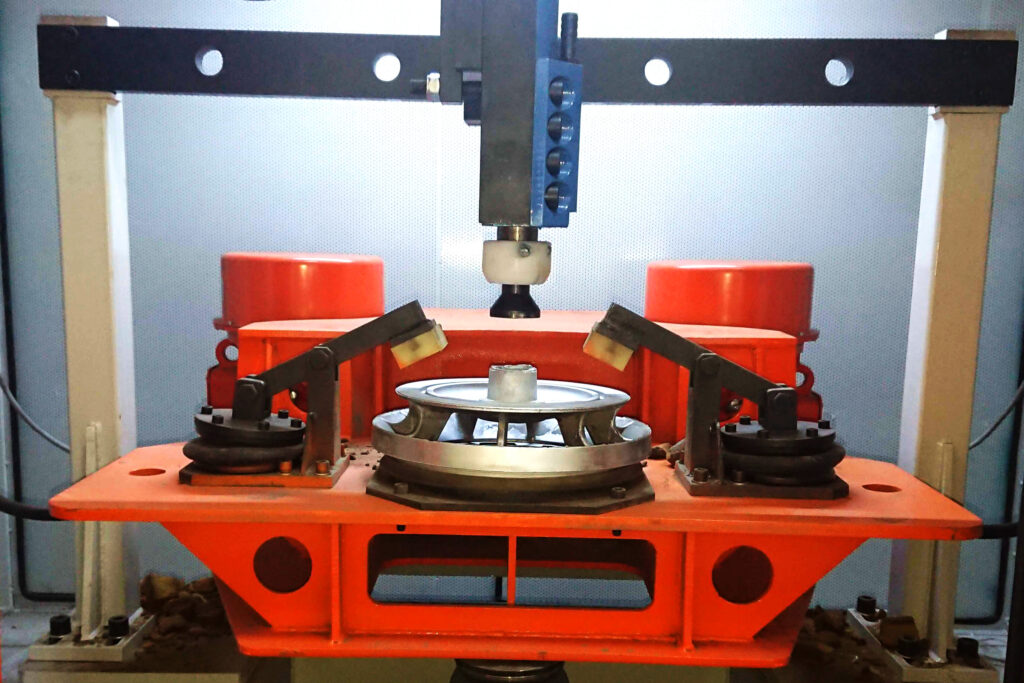

The DC-70 decoring machine uses high-frequency decoring hammers to strike the casting sprue, breaking the internal sand core into pieces. The fragments then flow out through the sand outlet, achieving fast removal of the casting’s internal sand core.

The operation is efficient and labor-saving, while ensuring the casting remains intact and its surface quality is maintained. It is an ideal choice for modern casting sand removal.

Rotation and Hammering for Core Sand Removal

DC-70R Rotary De-coring Machine

This DC-70R Rotary Decoring Machine combines high-frequency pneumatic hammering with a rotating mechanism. The casting rotates while being hammered, promoting the breakup and discharge of the sand core. It is well-suited for aluminum alloy castings with relatively simple internal cavities.

Hammering and High-Frequency Vibration for Core Sand Removal

DC-70V Vibration De-coring Machine

This DC-70V vibration decoring machine is designed for removing sand cores from aluminum alloy castings such as cylinder heads, swing arms, sub-frames, housings, and air pipes. The decoring process combines hammering with high-frequency vibration for efficient and thorough sand removal.

Rotation, Hammering, and High-Frequency Vibration for Core Sand Removal

DC-70VR Rotary & Vibration De-coring Machine

The DC-70VR rotary vibration decoring machine combines hammering, rotation, and high-frequency vibration for efficient sand core removal.

During operation, the decoring hammer strikes the casting sprue at high frequency, loosening the internal sand core. The coordinated vibration and rotation then break the core into pieces and discharge it through the sand outlet, ensuring complete and thorough decoring.

How Decoring Machine Works

Our decoring machines are designed for foundry applications, ensuring fast, reliable, and cost-effective sand removal. Perfect for improving productivity and achieving cleaner castings.