Pneumatic De-coring hammer is a device that uses pneumatic impact to vibrate and strike castings made of aluminum alloy, cast iron, engine cylinder, steel cover, exhaust pipe, pump body, valve body, pipe fittings, shell parts, etc. that use core sand casting process, thereby removing the core sand in the product cavity.

The working principle of pneumatic decoring hammer is mainly based on the principle of gas compression and release. It can remove the sand cores of various cast iron, aluminum and steel castings. Pneumatic decoring hammer has fast and reliable decoring, short cycle time, safety and environmental protection, high efficiency, low energy consumption, and is suitable for large, medium and small batch production.

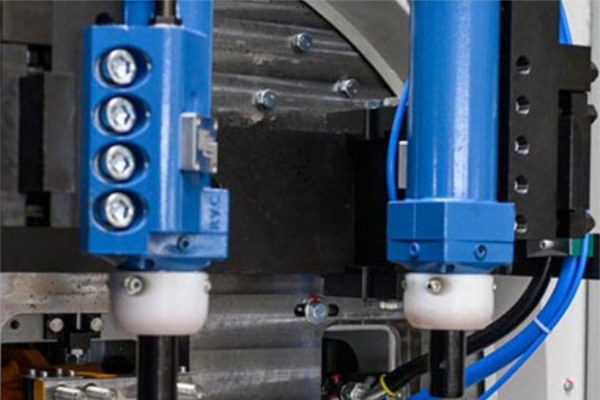

Overview Of The Structure Of Pneumatic De-Coring Hammer

- Cylinder: used to provide power to make the decoring hammer work.

- Piston: connects the cylinder and the De-coring hammer to transmit the power of the cylinder to the De-coring hammer.

- Pneumatic decoring hammer: used to remove the core shaft.

- Control system: used to control the operation and stop of the equipment.

Conclusion

Pneumatic De-coring hammer is small in size, low in failure rate, long in service life, and easy to install and maintain. High-frequency pneumatic decoring hammer only needs compressed air as the power source, consumes little gas, is safe and energy-saving, and can be used in humid, dry, dusty or explosive environments, so it is widely used in foundry workshops for sand decoring!