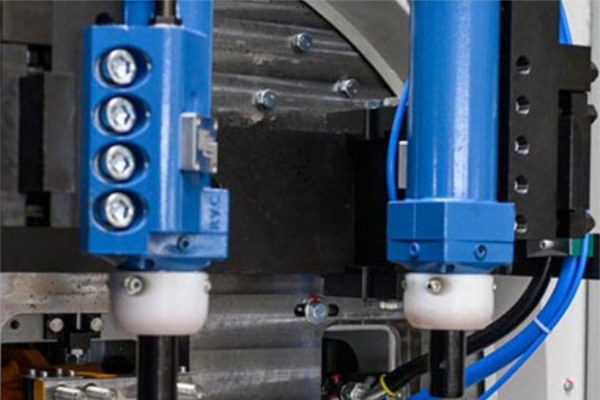

The de-coring hammer can directly strike and vibrate the casting, breaking up the sand core inside the casting more quickly. And the pneumatic de-coring hammer can easily knock down the vibrated object without damaging the vibrating object.

The de-coring hammer has the advantages of pneumatic high-frequency vibration, fast speed, high frequency, easy installation and maintenance. The de-coring hammer is mainly used to remove the sand core inside the casting, including aluminum castings, steel castings, or other alloys.

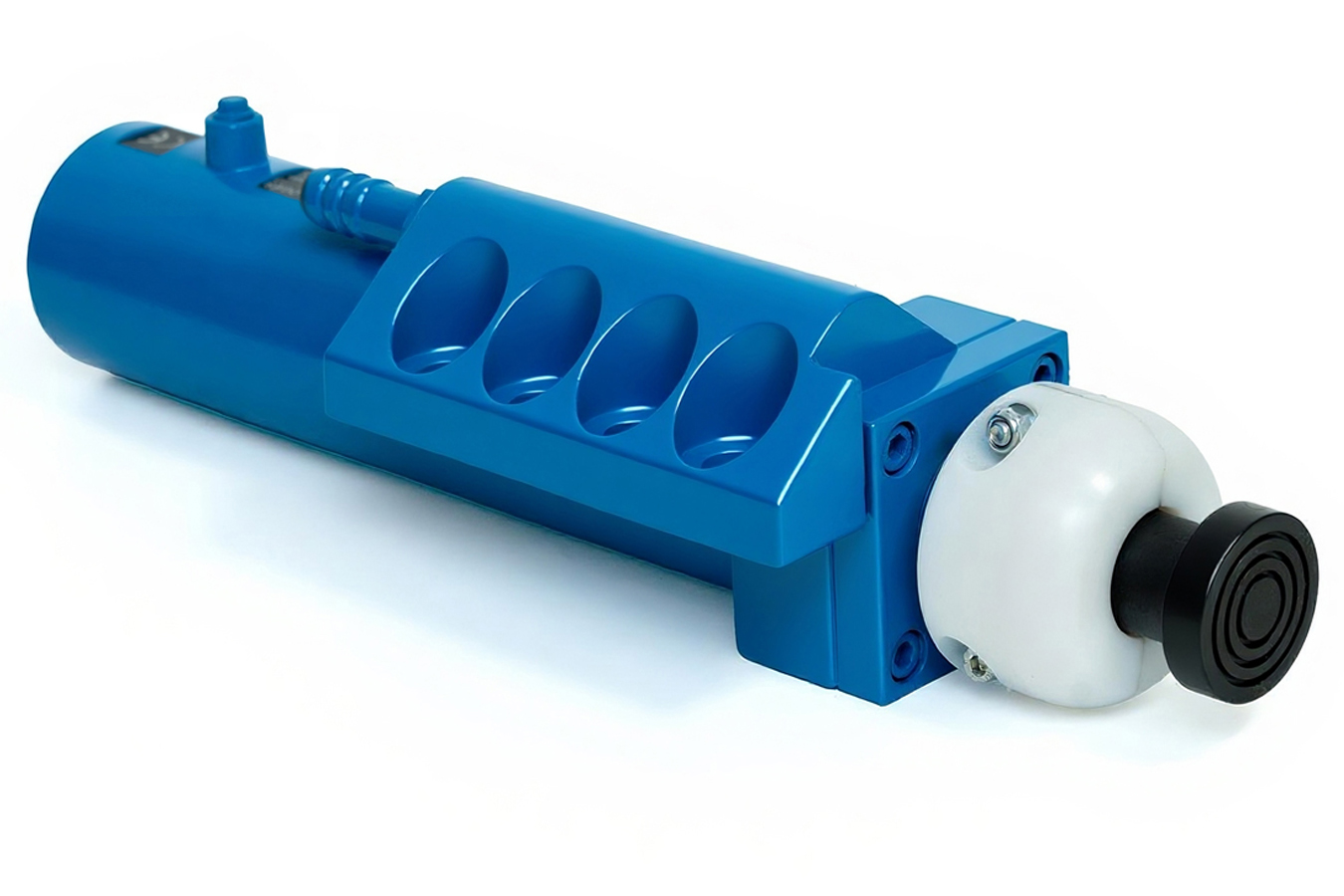

Working Principle Of The De-coring Hammer

Using compressed air as the power source, once the air source switch is turned on, the inner shaft tube assembly inside the de-coring hammer is compressed and pushed out until the front hammer head presses the workpiece to be de-cored; the switching of the air flow reversing plug position in the inner shaft tube assembly guides the air flow to make the piston rod perform periodic high-frequency reciprocating impact hammer movement; the high-frequency impact force generated is transmitted to the workpiece through the hammer head, and then to the sand core inside the workpiece, which plays the role of shattering the sand core and separating the sand core from the workpiece, thereby achieving the purpose of efficiently removing the sand core.

Four Major Features Of The De-coring Hammerr for casting

- Feature 1: High vibration frequency (frequency can reach 1200c/min).

- Feature 2: The core removal hammer has a significant sand removal effect. The casting is cleaned of sand cores in a shorter time after being struck by the air hammer. The sand removal of a workpiece is completed in a few seconds to 60 seconds, and the sand removal rate is high.

- Feature 3: Safe and reliable. It only needs air source to work, safe and explosion-proof, and suitable for various environments.

- Feature 4: The product is easy to maintain and has a relatively long service life.

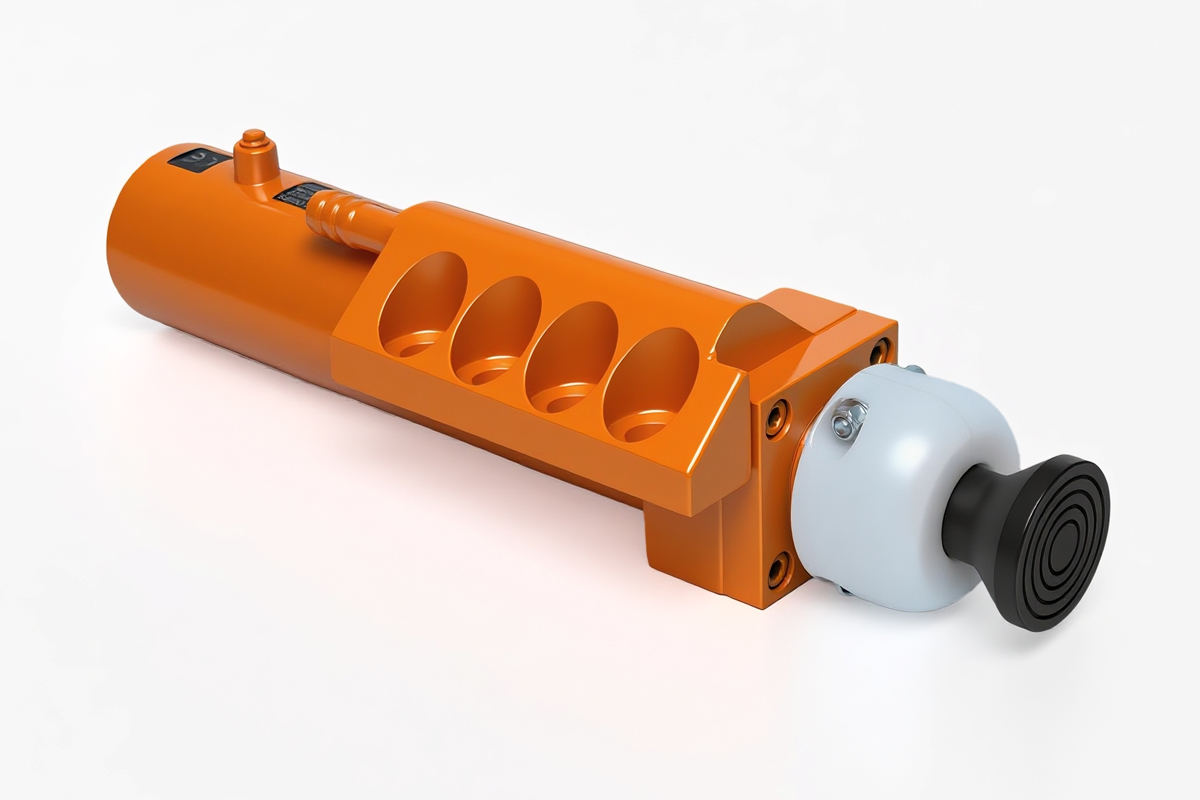

Conclusion

Since the core removal hammer only needs compressed air as the power source, the gas consumption is small, it is safe and energy-saving, and it is also an ideal device for use in freezing or high temperature environments. It is suitable for humid, dry, dusty or explosive environments, so it is widely used in foundry workshops for sand removal!